SUPPORT

WHY USE an NDT®?

01

ACCURACY

The NDT® uses electrical impulses to detect nails, nail holes, cuts, tears and bad repairs that are not often visible to the naked eye. Hidden flaws and small punctures can be repaired before they develop into real problems.

02

SPEED

With the ability to test up to 200 tires per day the NDT® allows inspection of every casing prior to buffing. Since it is independent from buffing it does not slow down the retreading process.

03

ECONOMY

The NDT® was designed to provide the services you expect at a price that is right for all retreaders without increasing time or cost.

04

FLEXIBILITY

Tires can be inspected at anytime; prior to buffing, after buffing, after repairs or even as a final inspection after retreading.

faqs

My machine is missing flaws, what is wrong?

The following describes a sequential and logical order of trouble shooting the NDT and is common for all model NDT machines.

First, check the high-voltage cabinet to ensure that the critical frequency is good. Measure the 1 Meg, 20 Meg, 75 Ohm, 5 K Ohm, and 150 Ohm resistors (How to measure the resistors), measure the High-Voltage Coil, clean and cycle the High-Voltage Relays, gap the Capacitors (How to gap the capacitors).

Wipe down the cabinet and vacuum out all of the dust and debris. If there is corrosion, install an NDT-Kit, Hawkinson Part Number H05-0008. Install an NDT-Kit once every five years or as needed.

Check the 2-amp breaker to ensure that the breaker did not disengage. If the breaker is disengaged, click on the Hyperlink for the 2-amp breaker.

Check that the coax cable, current transformer, and detector board cables are all connected, and there is no obvious damage. If damage is noted, or questionable, click on the Hyperlink for a specific component for specific directions.

Check that the probe is in alignment.

Try a spark test (spark test directions).

What kind of flaws can the NDT® detect?

Depending on the construction of the tire (steel or bias) the NDT can detect the following:

Steel Belted

- Through holes that are between the probe chain bar and the ground roller (A)

- Partial holes inside the tire that extend to the steel belts (B)

- Partial holes between the steel belts of the tire and the ground roller (C)

Bias Ply

- Through holes that are between the probe chain bar and the ground roller (A).

- Embedded objects that touch either the chain bar or the ground roller (B and C).

I have an NDT® that did not arc to an obvious flaw why not?

Hawkinson—If potential exists for electricity to arc to a flaw the NDT will arc every time. If the NDT did not arc than no potential existed. After checking the NDT for mechanical failure the next step is to analyze other reasons why an NDT will not arc to a flaw:

- When a tire is spread on the NDT, the degree of spread can vary. When a tire is spread, flaws can open, or flaws can close. If a flaw closes tightly it is possible that potential to arc does not exist, therefore, no arc will occur.

- A conductive object is imbedded within the tire and surrounded by nonconductive properties. There is no potential for an arc of electricity to occur therefore no arc. (This problem can be reduced by adding an NDT after the buffer or as a final inspection unit. Occasionally, an imbedded piece of metal will be missed by the NDT and will be forced out of position by the buffer or a pressure chamber. Materials, labor, and adjustments can be reduced by adding NDTs to inspect tires after buff and during final inspection.

- If the probe or ground roller does not touch the flaw, no potential can exist. (This problem is typical. Sidewall wires on the probe become deformed and do not touch parts of the tire. Replacing sidewall wires regularly can reduce missed flaws.)

- The rotation speed of the tire causes a flaw to pass under the probe when no electricity was available to arc–The NDT makes a distinct ticking sound as high voltage is applied. When a ticking sound is heard, electricity is applied to the tire. Between ticks, no electricity is applied to the tire. The slower the NDT rotates the likelihood of an arc to occur is greater. The average time to “electrically” inspect a tire is less than 32 seconds. However, most retreaders who use the NDT also use it to conduct a visual inspection and some use the NDT to make repairs to the tire at the same time as inspection. Install a manager’s speed kit to ensure your operator does not electrically inspect tires too fast – Motor Speed Kit 1, Motor Speed Kit 2.

The NDT is a tool and requires a well-trained operator to maximize the NDT guarantee.

My machine will not arc to any flaw, why?

Hawkinson—If potential exists for electricity to arc to a flaw the NDT will arc every time. If the NDT did not arc than no potential existed. After checking the NDT for mechanical failure the next step is to analyze other reasons why an NDT will not arc to a flaw:

- When a tire is spread on the NDT, the degree of spread can vary. When a tire is spread, flaws can open, or flaws can close. If a flaw closes tightly it is possible that potential to arc does not exist, therefore, no arc will occur.

- A conductive object is imbedded within the tire and surrounded by nonconductive properties. There is no potential for an arc of electricity to occur therefore no arc. (This problem can be reduced by adding an NDT after the buffer or as a final inspection unit. Occasionally, an imbedded piece of metal will be missed by the NDT and will be forced out of position by the buffer or a pressure chamber. Materials, labor, and adjustments can be reduced by adding NDTs to inspect tires after buff and during final inspection.

- If the probe or ground roller does not touch the flaw, no potential can exist. (This problem is typical. Sidewall wires on the probe become deformed and do not touch parts of the tire. Replacing sidewall wires regularly can reduce missed flaws.)

- The rotation speed of the tire causes a flaw to pass under the probe when no electricity was available to arc–The NDT makes a distinct ticking sound as high voltage is applied. When a ticking sound is heard, electricity is applied to the tire. Between ticks, no electricity is applied to the tire. The slower the NDT rotates the likelihood of an arc to occur is greater. The average time to “electrically” inspect a tire is less than 32 seconds. However, most retreaders who use the NDT also use it to conduct a visual inspection and some use the NDT to make repairs to the tire at the same time as inspection. Install a manager’s speed kit to ensure your operator does not electrically inspect tires too fast – Motor Speed Kit 1, Motor Speed Kit 2.

The NDT is a tool and requires a well-trained operator to maximize the NDT guarantee.

The NDT® arced but did not stop automatically while in the start (automatic) mode, why?

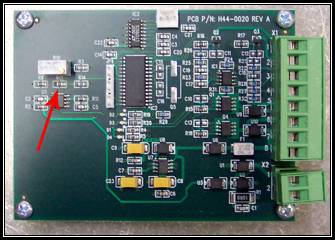

Detector Board (Instructions to Conversion Kit for New Detector Board)

Detector Board Outputs

(read more 1) Occasionally, due to atmospheric conditions, or variance in the input voltage of the NDT, the sensitivity of the Hawkinson Detector Board may need adjustment. (Old Board Adjustment, New Board Adjustment)

To adjust the sensitivity of older detector circuits

- Set digital multimeter to DC volts

- Connect the meter’s DC negative to 12 Volts DC Negative (Use the black wire that is connected to the wiring harness of the new computer board.)

- Connect the other meter lead to TP6

- Adjust the potentiometer next to TP6. Turning the potentiometer counterclockwise increases the sensitivity. Turning the potentiometer clockwise decreases the sensitivity

My test tire did not trigger a flaw condition, why?

Hawkinson—Test tires are NOT an effective way to determine the NDT’s reliability. Typically, test tires are created by drilling or puncturing holes in a tire. Drilling or puncturing a hole in a tire will cause a very clean hole. Whereas, a tire that is punctured by a nail on the road will collect contaminates, which may contain conductive material and will push the nail in and out of the tire many times. The best way to test the reliability of the NDT should be accomplished by conducting the spark test. The spark test is explained in the owner’s manual. The NDT guarantees that the NDT will reduce the adjustment rate compared to visual inspection alone.

How the NDT® can save your money.

Customer—Can the NDT save me money?

Hawkinson—Compare the cost of the NDT to the cost of adjustments. Tests conducted by an independent consultation service proved that the NDT will find flaws in tires that are missed during visual inspection. In fact, the independent testing services concluded that the NDT would find significantly more flaws in tires compared to visual inspection. Compare the NDT to other types of inspection equipment such as shearography, x-ray, or ultrasound and the NDT will be the most affordable, efficient, and reliable machine. The upfront cost of the NDT is less than many of the other inspection methods and long-term maintenance is typically minimal. Labor costs are less than many other inspection methods. Production costs can be reduced; reducing the number of times buffer blades must be replaced from missed objects in the tire; the amount of material waste due to undetected flaws is reduced. The NDT is durable and dependable and has been the standard in North America for the last 20 years.

How does the NDT® work?

Critical Frequency

Imagine the high voltage cabinet as a radio. The radio transmits a specific frequency, which is created by the high-voltage power supply, resistors, and gapping of the capacitors. The specific frequency travels up the antenna, which is the high-voltage output wire to the tire. A receiver, which is the current transformer, intercepts the specific frequency and sends the signal through the coax cable to the detector circuit. The detector circuit listens for changes to the specific frequency. When an arc occurs, the detector circuit realizes a change has occurred, which then triggers a flaw condition. If an arc occurs anywhere along the antenna, the detector will trigger a flaw condition. The arc does not have to occur in the tire.

Who uses electronic tire inspection, NDTs®?

There are many companies that use the Hawkinson NDT to ensure that their retreaded tires are of the highest quality. For example:

Michelin

Please take a look at this link and download the Nail Hole Inspection video.

Wingfoot / Goodyear

The link shows a picture of the NDT-II made by Hawkinson, which is used by Goodyear.

Bridgestone / Bandag

The link below shows the NDT-IIB being used by in Bandag’s retread process at approximately the 2:00 minute mark.

When I press the start button, nothing happens, why?

The Start Button does not work, why?

This is a common problem with the NDT and is usually a simple problem to fix. Typically, the problem occurs because there is a small pinhole in the probe wire, or the high-voltage output wire. Replacing these two wires nearly always fixes the problem.

If the problem continues to persist after replacing the probe wire and high-voltage output wire, the machine may have a defective detector circuit board. To check the detector board, disengage the 2-amp breaker in the operator’s console. Next, place a tire on the machine, and begin the electronic inspection. When the Start Button is pressed, the yellow flaw light turns off and the motor should turn. There will be no high-voltage. However, the motor should turn, and the green timer over light (Test Complete) should illuminate after approximately 30 seconds. If this is, the case detector board is not the problem.

However, if the motor does not turn check the 12-volt DC power supply, and 12-volt DC relays, and cables between the detector circuit board and operators console. If they are good, replace the detector circuit board.

If all else fails replace the coax cable, and if the problem persists, the only other component that can cause this situation is the current transformer, so replace that as well.

My motor won’t turn, why?

Six systems can cause the motor to stop turning. Five of the six can be analyzed, and by process of elimination, the sixth can be diagnosed.

First, check the 12-volt relays, and 12-volt power supply. Next, check the 50 K potentiometer. Next, check the direction switches on the operator’s console, then on the front remote location. Next, check the motor contactors (not all NDT machines have motor contactors). Finally, check the motor. If all of the aforementioned parts are good, replace the motor control board.

The swing arm won’t swing in, out, up, or down, why?

Arm Swing In/Out

The normally open contact is used to supply 120 VAC to the arm swing in/out solenoid and to the Inside UP/Down switch. If the probe does not swing into the tire, the normally open contact may not be allowing electricity to pass. Ensure that the selector is set to the in position, electricity should be on both sides of the normally open contact. If electricity is not on both sides of the contact than replace the contact. Note, the probe will not go up or down if, the arm swing contact is not working.

Additionally, if the probe will not swing in or is mushy check the slow start.

The 2-amp circuit breaker disengaged, why?

2-Amp Circuit Breaker

The 2-amp circuit breaker protects the 50 KV power supply. If there is no high voltage the first place to check is the 2-amp circuit breaker to ensure it has not been disengaged. If the circuit breaker is disengaged that signifies that there is something wrong with the high-voltage circuit. Usually, this means that that one of the following has failed: 1) the 50 KV power supply, 2) the 1 Meg or 20 Meg resistor, or 3) either of the capacitors. Do not continue to operate the NDT if the 2-amp circuit breaker disengages without examining the cause.

What maintenance should I do to the NDT®?

NDT® User Maintenance (User Maintenance Schedule)

Probes should be vertical, centered in the tire, and properly placed over the metal drive roller.

Air should be set to specs as per operator’s manual. Never adjust air pressure to compensate for dirty, sticking V-bearings.

Worn and broken items such as sidewall wires, plastic paddles, roller bearings, spread rollers, and key chains hinder performance of the NDT®. It is not necessary to over-tighten the screws that hold the sidewall wires in place.

Inspect the NDT® for broken, worn, or wearing parts. Do not wait for a worn part to fail before replacement.

Pay close attention to:

- high voltage wires

- black coaxial cable

- loose screws

- tie-wraps

- ground straps

- resistors

- switch activators and contacts

The back cabinet contains high voltage parts, which can wear and should be checked. USE CAUTION! Speak to a Paul E. Hawkinson® technician before entering this cabinet.

Basically, there are two functions of the NDT® that allow it to find flaws in tire casing:

- Voltage is applied to the casing that creates an electrical arc when a flaw is present.

- The detector circuitry senses electrical current changes when an arc occurs.

The gap between the carbon balls in the high-voltage cabinet is the only adjustment the user has control over that can affect the current applied to a tire casing. The gap should be 11/16 inch. Speak to a technician before attempting to measure or adjusting the gap.

Sensitivity is adjusted by a potentiometer located on the detector circuit board. Hawkinson presets this at 4 volts on older detector circuit boards, and 1.654 on new detector circuit boards.

A clean machine works better and looks better. Follow these suggestions for proper NDT maintenance:

Engine de-greaser works well for cleaning the drive roller, v-rails, and other parts where heavy gunk collects.

How do I change the sensitivity of the detector circuit board – old detector circuit?

Detector Board Outputs

(read more 1) Occasionally, due to atmospheric conditions, or variance in the input voltage of the NDT, the sensitivity of the Hawkinson Detector Board may need adjustment. (Old Board Adjustment, New Board Adjustment)

To adjust the sensitivity of older detector circuits

- Set digital multimeter to DC volts

- Connect the meter’s DC negative to 12 Volts DC Negative (Use the black wire that is connected to the wiring harness of the new computer board.)

- Connect the other meter lead to TP6

- Adjust the potentiometer next to TP6. Turning the potentiometer counterclockwise increases the sensitivity. Turning the potentiometer clockwise decreases the sensitivity

How do I change the sensitivity of the detector circuit board – new detector circuit?

To adjust the sensitivity of the new detector board follow these steps:

- Set digital multimeter to DC volts

- Connect the meter’s DC negative to 12 Volts DC Negative (Use the black wire that is connected to the wiring harness of the new computer board.)

- Connect the meter’s DC positive to the left side of R13. R13 is a resistor located between R9 and R14. The left side of R13 is the side facing R9.

- The factory setting should be 1.654 volts DC.

- If the customer complains of missing flaws the sensitivity setting can be changed by adjusting the potentiometer R10 located directly above R13. Adjusting R10, by turning the screw counterclockwise will increase the sensitivity, and lower the DC volts displayed by the meter. Rotating the screw clockwise will decrease the sensitivity, and increase the the DC volts displayed by the meter. Settings of less than 1 VDC will typically be too sensitive, and trigger a flaw condition even if there is no flaw. Settings greater than 2 VDC will typically not be sensitive enough, and the detector will not trigger a flaw.

New Detector Circuit Adjustment Resistor and Potentiometer

In some cases the old detector circuit fails because one or more of the chips on the board fails. Replacement of the chips is an alternative to replacing the entire detector circuit board. However, most chips are difficult to source because the original equipment manufacturer no longer produces the chips.